Green concrete is more important than you think

But its tough to fix, which is why we all need to start finding solutions now

The production of concrete, or more accurately cement, already accounts for between 5-8% of global GHG emissions. This is a similar scale to the GHG emissions of passenger cars - but it gets a lot less attention. We think this needs to change, especially as increasing urbanisation will mean we are likely to use more concrete in the future, not less.

Unlike passenger cars, where we have a financially and technically viable alternative (electric vehicles or EV's), the current low carbon alternatives to traditional cement are niche products, and they look hard to scale. We will need a lot of work, and investment, over the coming decade or more if we are to get close to decarbonising this important industry. And we need to start now.

Concrete is the most widely used man-made material, commonly used in buildings, roads, bridges and industrial plants. And it's the second most used resource, only after water. It's hard to imagine much of our world without it. And our best estimate is that we are going to be using a lot more of it in the future.

But producing the cement needed to make concrete already accounts for 5-8% of all global greenhouse (GHG) emissions. That is very similar in scale to the GHG emissions from passenger cars (c. 7.1%).

Let’s pause a minute here…. making concrete generates as much GHG emissions as all of the world's passenger cars put together. How much attention does reducing passenger car emissions get? Pretty much every day we see a major story in the press or online about Electric Vehicles. But how often do you read about concrete?

One reason is that concrete is almost invisible. It's almost everywhere, but in a way that means it slides into the background. It's not as obvious to the general population as cars are. But the other reason is that decarbonising concrete is tough. Not impossible, but really hard to do in a financially viable way. And so we don’t have an Elon Musk (of Tesla fame) launching a new concrete, - forcing the incumbents to take action.

The three main questions we need to be able to answer

There are three main questions we think people who care about sustainability need to be able to answer about concrete/cement production.

Why does it produce so much CO2?

Is there a better way of producing it that produces less GHG emissions? and

Is there an alternative material that does the same job but better?

And for questions 2 & 3, it's not enough to say, this solution works on a technical basis. It also needs to be financially viable. If the alternatives end up being more expensive, then we are going to need subsidies, and probably very large ones.

Newly industrialising countries use a lot of cement

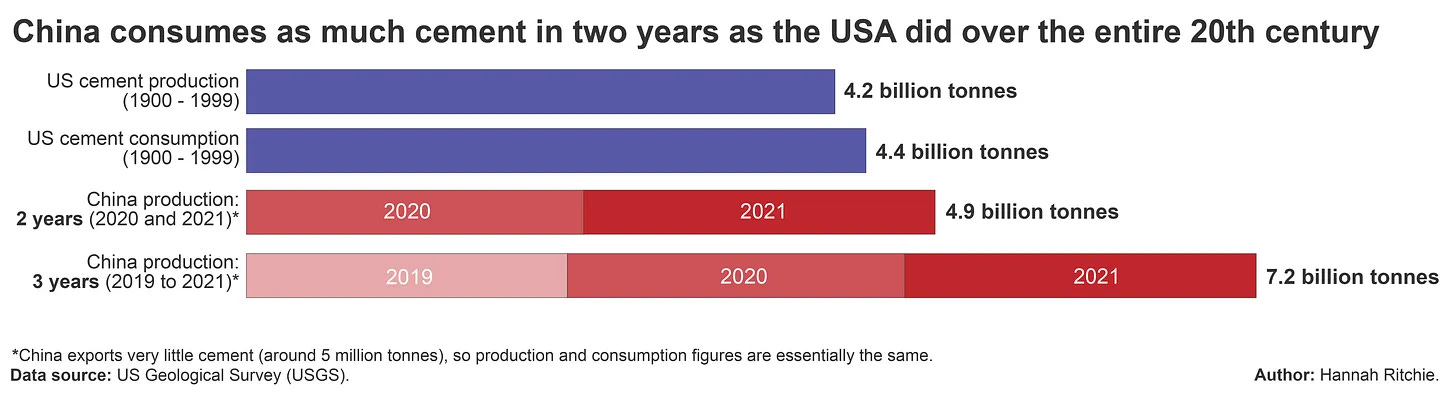

And one last thing before we move on. Since 1985, China has become the largest producer of cement and they consumed more cement in 2 years (2020 to 2021) than the U.S. consumed in the entire 20th century. In 2018, China’s cement production accounted for ~56% of global cement production. This is all from fact checker extraordinaire Hannah Richie

Now, this is not because China uses cement for anything unusual. It's just because it's industrialising so quickly. And if other countries follow a similar route, then we could see the world using a lot more cement, even if the rate of growth in China starts to slow.

How do we currently make cement?

When you think about it, concrete is pretty amazing. You mix gravel (aggregate) with sand, some grey powder (cement) and a bit of water and hey, you get something that is pourable, can take up almost any shape, and yet once it sets, it's very hard and strong. And it's the chemical properties of cement that make this happen. But sadly, it's this same cement that makes up nearly all of the GHG emissions produced in making concrete.

We will park for now the environmental impacts of gravel extraction, and what happens at the end of a building's life, and focus today on how we make cement and why it generates so much GHG emissions.

It's actually a fairly simple process. We quarry limestone, crush it, and then it's “calcinated” at around 900 degrees Celsius to create lime. This is then heated to 1,450-1,500 degrees Celsius, in a rotary kiln, to create what is known as clinker. Finally, the clinker is ground to create cement.

So where do the GHG emissions come from? Typically, just over half come from the chemical reaction as the limestone is turned into lime. A further 40% come from burning fossil fuels to heat the kilns to the temperatures needed. And the last 10% of emissions come from fuels needed to mine and transport the raw materials.

This gives us a bit of a clue as to why decarbonising cement production is so tough. The first challenge is that the chemical process that releases the CO2 is an inherent part of turning limestone into cement. The production process just doesn't happen without this stage. To reduce these emissions we need to use something else other than limestone as a raw material, which is tough.

The second challenge is the high temperatures needed, up to 1,500 degrees Celsius. It's possible to electrify this, but the technologies to do this consistently are still in development. We can also use alternatives such as biomass or waste as an energy source - but supplies are limited and a lot of other decarbonisation technologies also want to use the same raw materials. And in some markets, such as Europe, around 43% of fuel consumption already comes from alternatives, so scaling this up further is difficult.

All of this means that there is unlikely to be a single simple solution to the challenge of decarbonising cement making. In our next blog on this topic, we look at some of the ideas that have been put forward, from alternatives to limestone, through to changes in how we design buildings.